Weaving process

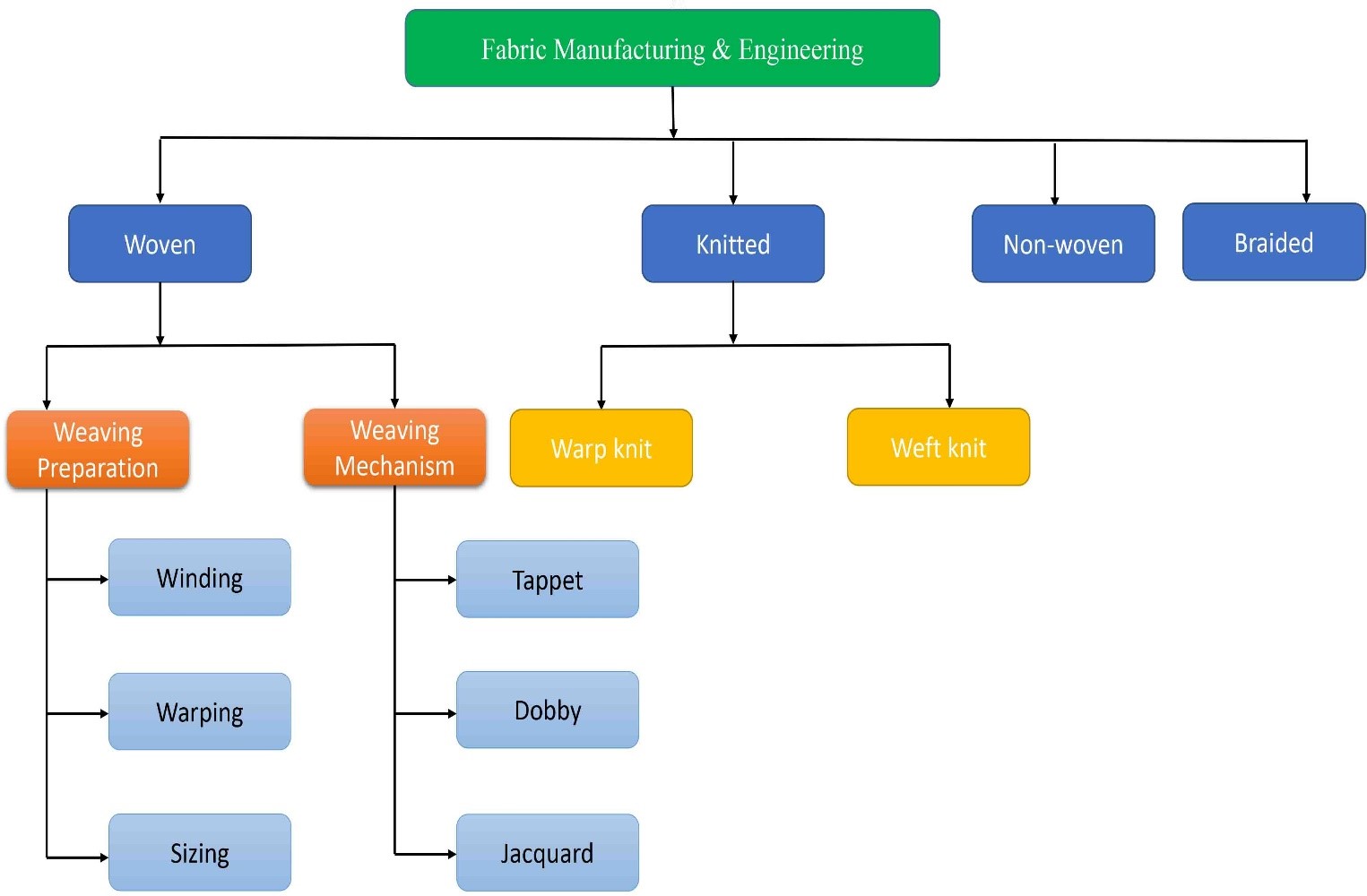

Basically the process of making woven fabric is known as weaving. Weaving Flow chart of weaving The process of weaving related with yarn form spinning, doubling & twisting, winding, creeling, warping, sizing, drawing-in/drafting-in, denting, looming, ltying-in, weaving and grey fabric. This process is shown in the following chart:

WEAVING PROCESS FLOW CHART Study With Param Parmanand Lecture 01 YouTube

Weaving is the process of making cloth with two components, a warp, and a weft, and can be done by very simple techniques on a complicated loom. Preparing the Warp Yarns for Weaving Before their use on the loom, warp and filling yarns must be prepared for weaving.

D'source Weaving Process Making Process D'Source Digital Online Learning Environment for

Process Flow Chart of Weaving Technology We can classify of weaving flow chart. One is warp yarn preparation and another is weft yarn preparation. Flow Chart of Weaving (Warp yarn) Yarn from Spinning Section ↓ Yarn Preparation ↓ Warp Preparation ↓ Winding (Cone, Cheese, Spool, Flange, Bobbin) ↓ Creeling ↓ Warping ↓ Sizing/ Dressing (Jute) ↓

Process flow chart of yarn manufacturing. Download Scientific Diagram

There are three main steps of weaving preparatory process: Winding Warping Sizing Without these process Drawing-in and Tying-in are also done in weaving process. Winding process:

Textile Weaving Process Overview Explained TexConnect YouTube

Flow Chart of Woven Fabric Manufacturing: The actual process flow chart of weaving or woven fabric manufacturing has presented the below: Fig: Weaving process flow chart All the above processes have discussed below: Warp preparation:

Weaving process

In this video the detailed process of converting yarn into fabric is discussed. Complete weaving process is explained in the video above. Process flow chart.

Weaving Process Flow Chart

The following is the process flow chart of weaving technology. Fabric Manufacturing Process In Textile Industry: Flow Chart of Weaving (weavers beam preparation): Spinning bobbin for winding ↓ Roll winding for spool production ↓ Warp yarn preparation ↓ Cone winding or pre-winding ↓ Warping ↓ Sizing ↓ Drafting in or Drawing in ↓ Denting ↓ Looming ↓

Weaving process

Flow Chart of Looming Process in Weaving March 30, 2021 by textile-flowchart Looming Process in Weaving The process of preparing a loom before starting the weaving process is commonly known as looming.

Process Flow Chart of Weaving Textile Learner

Weaving Process Flowchart | Woven Fabric Production Weaving Process Flowchart | Woven Fabric Production Weaving Process Flowchart | Woven Fabric Production W.

Introduction to Spinning Process

Process Flow Chart of Weaving - Textile Learner - Read online for free.

Weaving

Weaving is the most popular way of fabric manufacturing. In the case of weaving, two sets of yarn are required to produce a cloth. One is warp, which runs along the length of the cloth and the.

Weaving Processes

Before weaving various process are done. After spinning process, yarn are divided into two forms, one is weft form and another is warp form. Weft yarns are produced by cop winding and warp yarn are. produced by wool winding process. In this article I will give working process flow chart of weaving.

Weaving Process Flow Chart

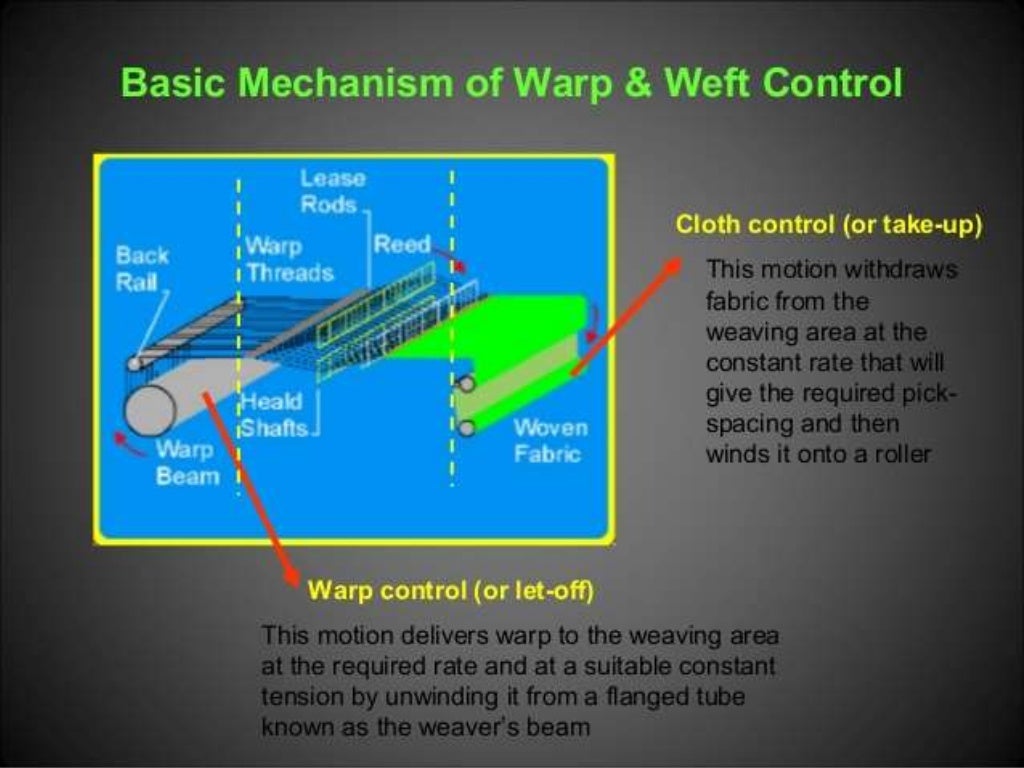

Textile - Weaving, Looms, Yarns: Woven cloth is normally much longer in one direction than the other. The lengthwise threads are called the warp, and the other threads, which are combined with the warp and lie widthwise, are called the weft (synonyms are "filling," "woof," and "shoot," or "shute"). An individual thread from the warp, of indefinite length, is called an end; each.

Weaving process

Weaving: The action of producing fabric by the interlacing of warp and weft threads is called weaving. In other words, weaving is the process of interlacing two sets of yarns at right angles.

Flow chart of Fabric Manufacturing? TE

Weaving: Weaving is the process of fabric manufacturing by interlacing two sets of yarn called warp and weft. In the weaving, many developed machines are using in the textile industries. For example, Air jet loom, Shuttle less loom, Jacquard loom, etc. Generally, three types of fabric are produced for garments and textile production.

D'source Making Process Silk Weaving Thirubuvanam D'Source Digital Online Learning

A textile product passes through several processes in its manufacturing before it becomes wearable. These processes include spinning, weaving, knitting, processing and garments manufacturing. The process flow chart of textile engineering is shown in below figure. Fig: Process flow of textile product manufacturing.